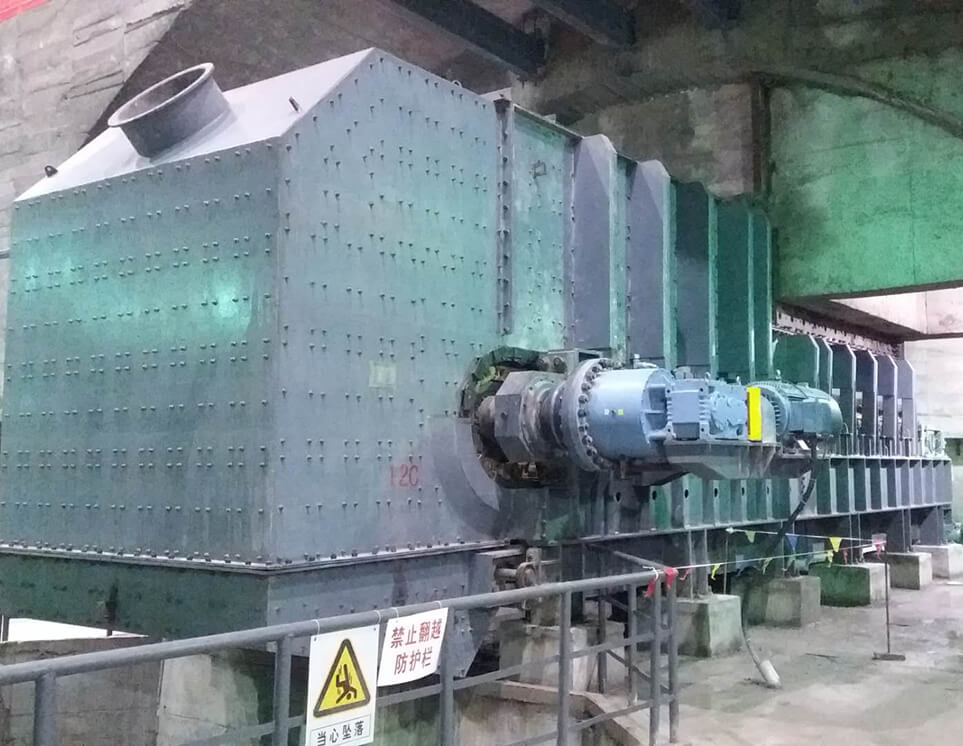

Apron Feeder

Apron Feeders are designed and manufactured to handle heavy, lumpy and abrasive materials. Its main function is to prevent surge loads to primary crushers, belt conveyors or other equipment. When the head sprocket starts running, the traction chain in the pan- chain device meshes with the sprocket,the roller travels along the track fixed on the frame,and drive the entire pans to move along the longitudinal center-line,in the meantime,the material is transported along the conveying line to the front of the body for continuous and uniform feeding.

| Handling Capacity: | > 6,500 m³/h |

| Conveying Length: | 3-25 m |

| Chain Speed: | 0.01-0.25 m/s |

| Max. Incline: | Maximum 25º |

| Max. Feeding size: | 1800 mm |

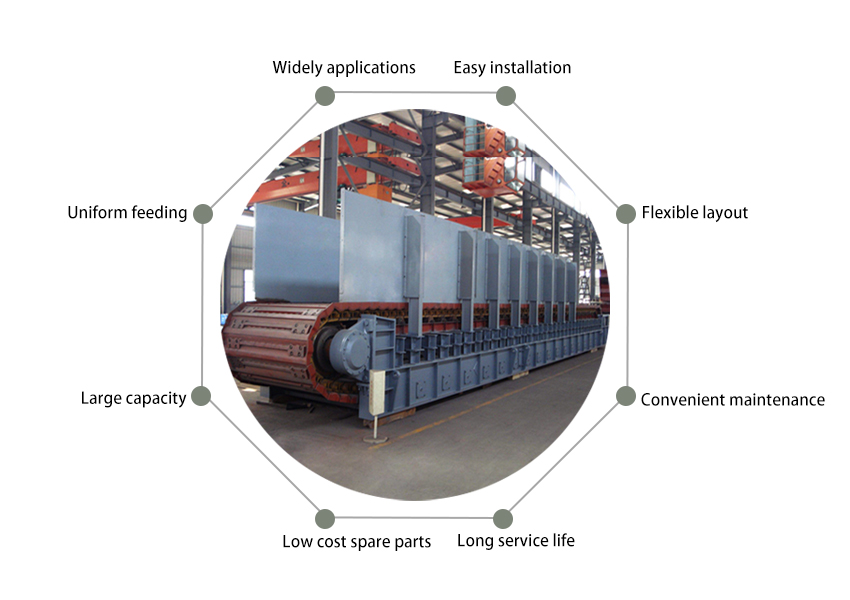

WHY EXCT APRON FEEDERS

Design: Experienced engineers team provides scientific and reasonable technical solutions of apron feeder for each end user.

Manufacture: Excellent tooling, skilled technical workers, 30+years of production experience to ensure the quality of apron feeder reliability.

Service: Fast after-sale service, sufficient spare parts reserve to ensure the longcycle stable operation of apron feeder.

Case: +200 successful cases of apron feeder in 40 countries and regions around the world.

APRON FEEDERS APPLICATIONS

Crusher feeding

Each apron feeder is tailor-made to suit all kinds of crusher.

Unloading of material of any size range,size up to 1,500 mm

Wagon unloading

Receive mine material directly from dump trucks,and can be combined with other equipment for unloading

Hopper discharge

Reasonable pan shape design for better cleaning and suitable for large block materials

Stockpile discharge

Heavy duty design ensures reliable material extraction, and unlimited on the height of material stockpile

APRON FEEDER DETAILS

Pans

Apron feeder adopt manganese pans or cast steel pans, with a longitudinal center rib, avoiding excessive deflections under high-impact loading and severely abrasive working conditons.

Sprocket

The rim of the sprocket is divided into three sections, which allow replacement of one segment at a time, without needing to dismantle chain, pans, skirts.

Chains

The track chain are made of heat-treated alloy steel, and made by drop forging, which can effectively prevent the external sands entering, thus, prolong the service life.

Rollers

Single flange tractor type rollers are mounted on support members in groups of 2 to 4 units to make disassembly and replacement easier.

SPECIFICATIONS

|

Apron Feeder Technical Specifications |

||||

|

Model |

Pan width |

Max feeding size |

Capacity |

Length |

|

BL800 |

800 |

350 |

50~350 |

2~15 |

|

BL1000 |

1000 |

470 |

100~510 |

3~20 |

|

BL1200 |

1200 |

650 |

120~595 |

3~20 |

|

BL1400 |

1400 |

680 |

140~850 |

6~20 |

|

BL1600 |

1600 |

700 |

320~1300 |

6~20 |

|

BL1800 |

1800 |

800 |

500~1560 |

8~20 |

|

BL2000 |

2000 |

1000 |

500~1850 |

8~20 |

|

BL2400 |

2400 |

1500 |

500~2700 |

8~20 |

|

BL2800 |

2800 |

1800 |

1000~4000 |

10~20 |

Apron Feeder brochure

Submit inquiry

Related Products

Contact us

E-mail: info@exctmach.com

Hotline: +86 18153098776

Wechat: +86 18153098776

WhatsApp: +86 18153098776