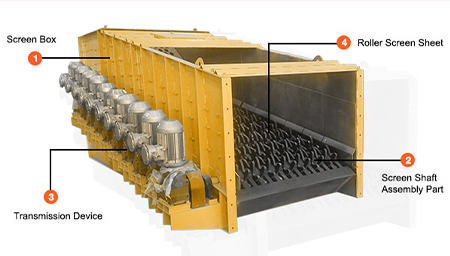

Roller Screen

FEATURES

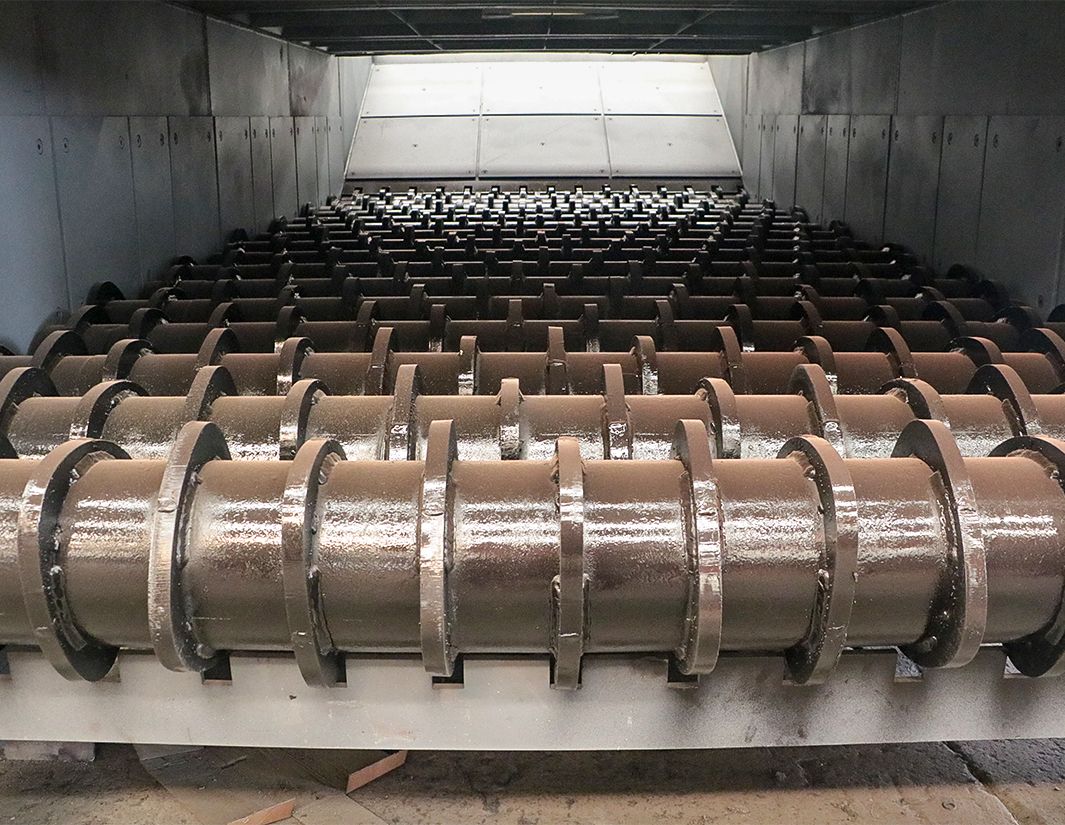

►The coil is made of alloy wear-resistant material, durable, easy to replace and repair.

►Wide adaptability to minerals and working conditions, not easy to clog, especially for high moisture minerals.

►Because the single machine uses single axis rotation, the roller motor with large starting torque is used, the whole roller transmission is stable and reliable, low noise, energy saving and environmental protection.

►With high throughput, it can handle wet and cohesive materials, and can be operated by a single gear motor or a chain driven by a motor with multiple screen shafts.

► The screen shaft rotates at uniform speed, and the whole machine has no vibration and high reliability.

APPLICATION

Roller screen is widely used in the screening of solid materials in coal, electric power, metallurgy, cement, sand aggregate, solid waste and other industries.

.jpg)