Conveyor Roller

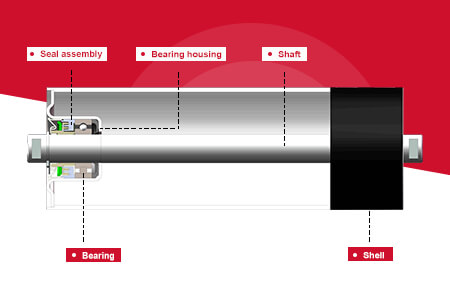

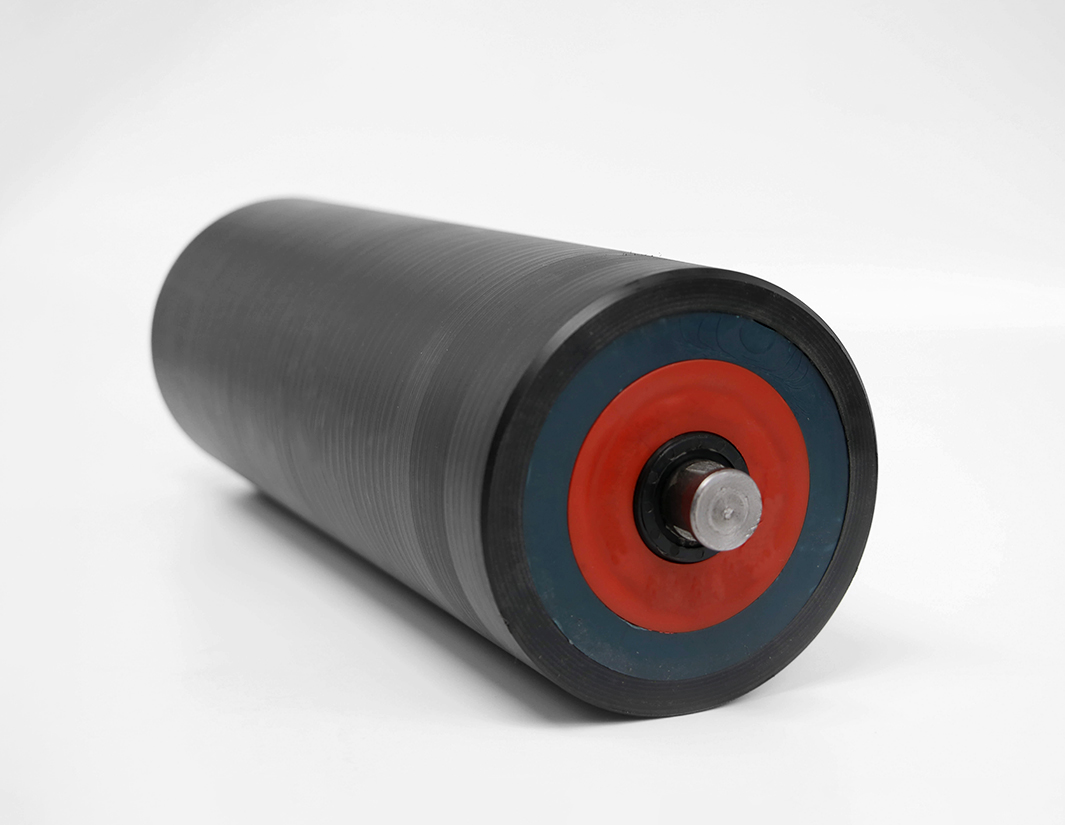

| • Seal Assembly |

| The seal assembly of roller is made of nylon, and the structural form is non-contact labyrinth seal structure. The inner and outer seals form a labyrinth passage with high precision, and the passage is filled with long-acting lithium-based grease, so that the roller has good waterproof and dustproof performance. |

| • Bearing Housing |

| The fabrication of the bearing housing consists of a multi-stage precision automatic pressing operation, which ensure high accuracy of bearing and sealing position. The roller pipes and bearing housing at both ends are 3mm fully fillet welded at the same time through CO2 gas shield double-gun automatic welding machine, which gives a minimum of 70% weld penetration, and ensures that the roller even under the high load and high speed operation, still strong and durable. |

| • Shaft |

| The shaft of roller adopts high precision cold drawn round steel after quenching and tempering treatment. Advanced Chamfer milling machine is used to perform accurate machining at both ends of the shaft, so as to ensure that the axial displacement of the roller is almost zero. |

| • Bearing |

| The bearing of roller adopts special C3 clearance grade deep groove ball bearing. Before assembly, the bearing of roller has been filled with lithium base grease and sealed permanently on both sides, which can realize lifetime maintenance free and extend the service life of the bearing. |

| • Shell |

| The shell of roller adopts special ratio-frequency welded pipe with small bending degree and small ellipticity. The advanced steel tube chamfer cutting off tool machine is used for precise machining of both ends of the pipe, which can effectively guarantee the concentricity of rollers and minimize the rotation resistance of rollers. |

BASIC INFORMATION

| Standard | JIS / CEMA / DIN / ISO / GB / AS / GOST |

| Roller Dia | 60-250mm |

| Roller Length | 150—3000mm Face Length |

| Shaft Dia | 20-60mm |

| Bearing Size | 6204-6312 |

| Bearing Brands | SKF, FAG, NSK, LYC, HRB, or ZWZ |

| Seal Type | Labyrinth Seal Structure |

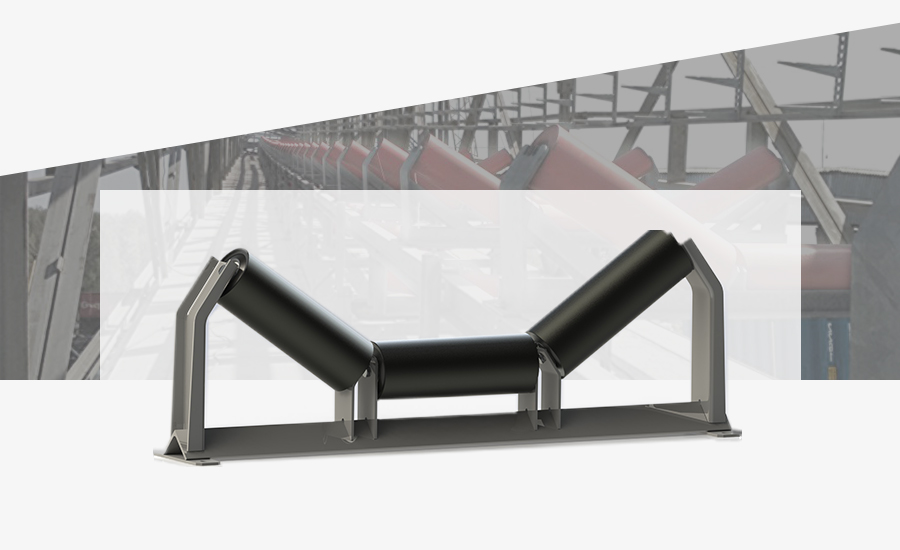

DIFFERENT TYPES OF

ROLLER SETS

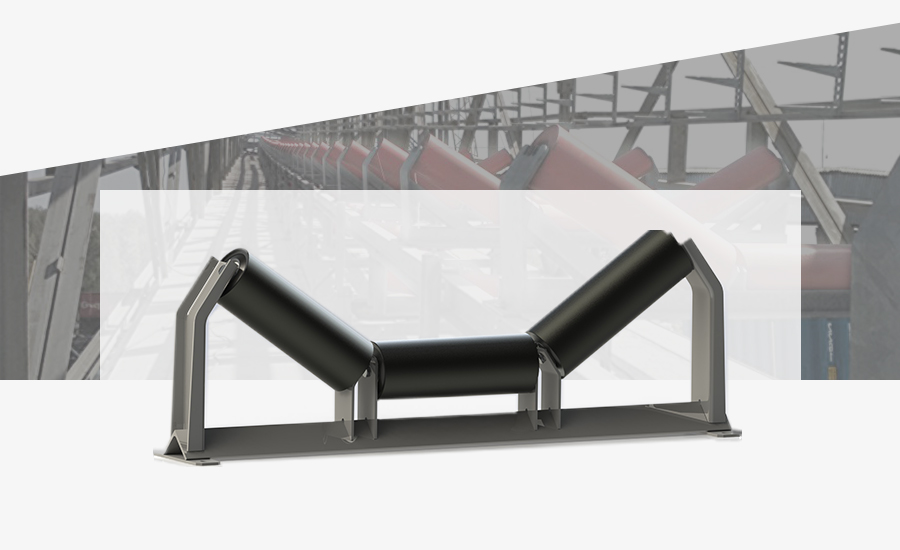

►Trough rollers are the most commonly used on the belt conveyor.

►The groove angles of EXCT trough idler sets are 10°,20°,35°,45°, and can customize production according to different standards by customers, such as JIS, CEMA, DIN, ISO, GB, AS, GOST.

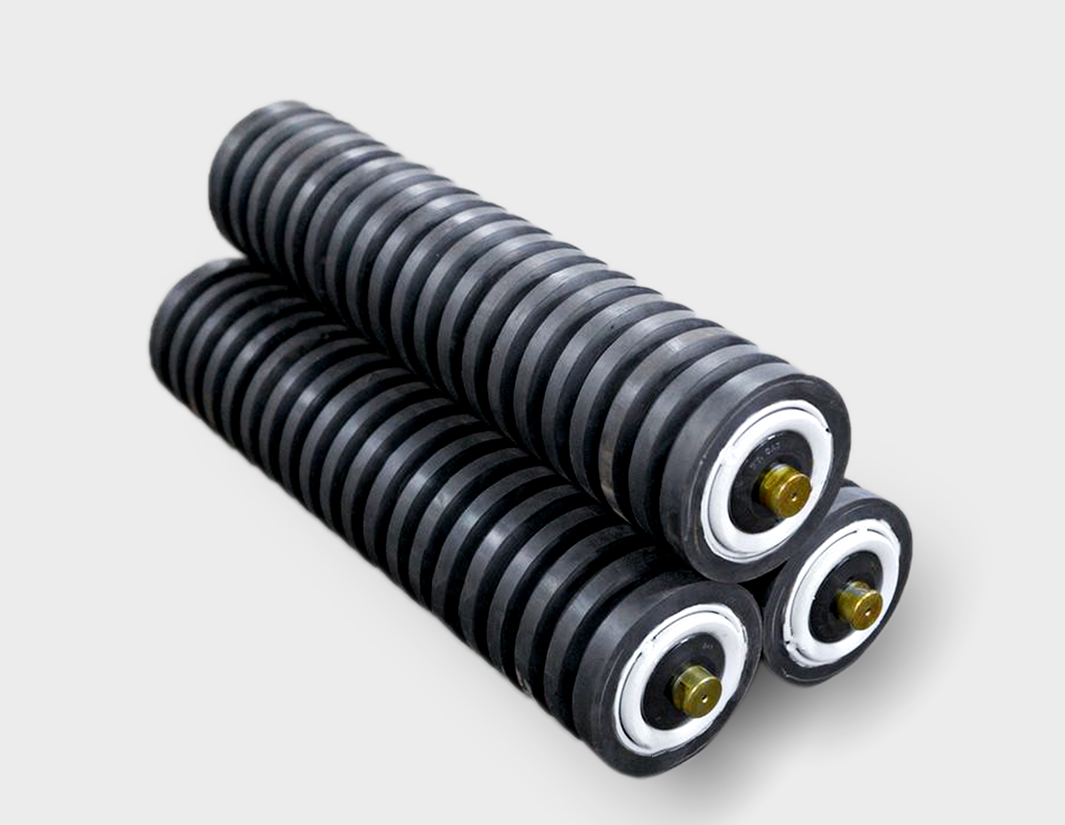

►The surface of the impact roller is rubber ring which absorb impact forces and minimize the damage of materials to the belt.

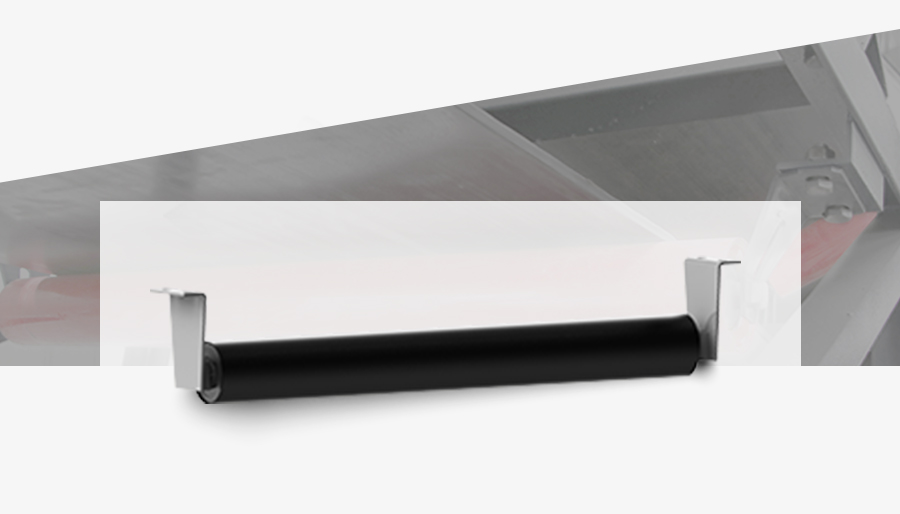

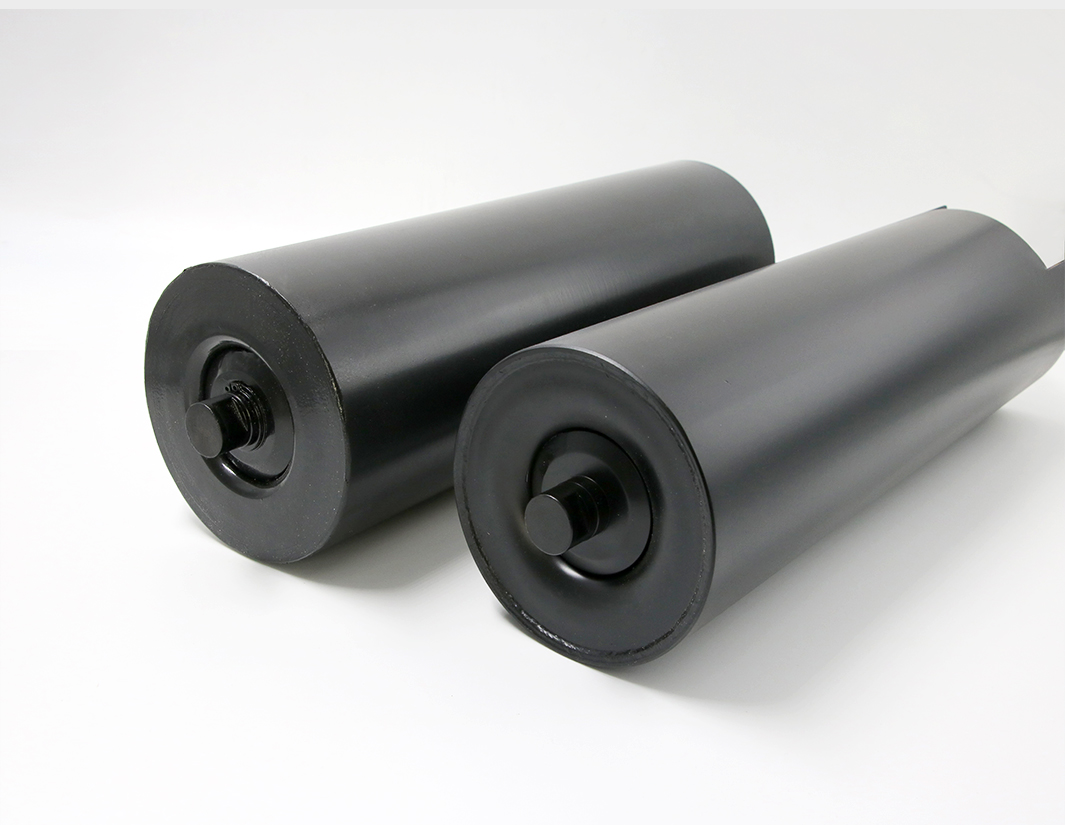

Return Roller

►The return rollers are used to support the belt to prevent stretching and sagging.

►EXCT return roller sets consist of a single roller mounted on two drop brackets.

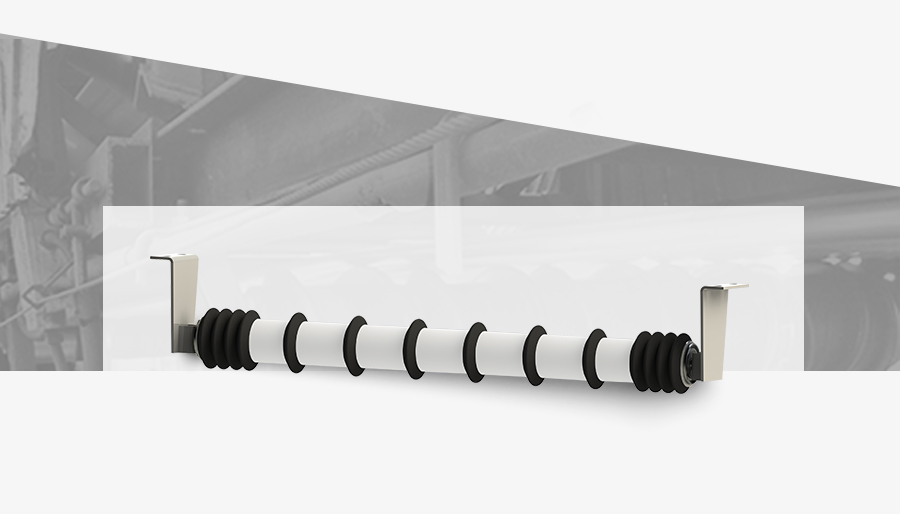

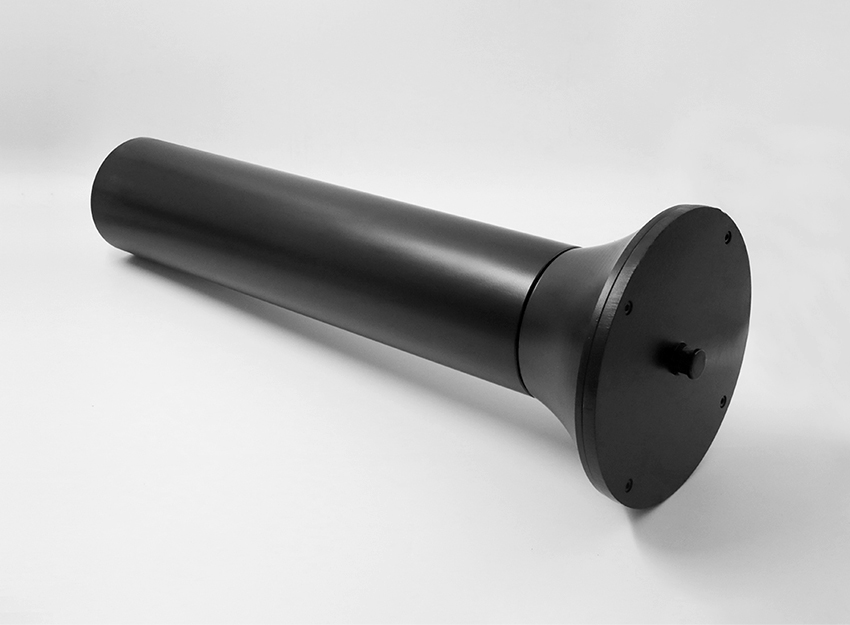

Comb Roller

►The comb roller can prevent the belt from deviating and clean the adhesive on the belt

►Especially, when the belt conveyor transports sticky materials, the most difficult problem to solve is how to remove the materials stuck on the belt. EXCT's comb rollers are one of the best options to solve this problem.

Self Aligning Return Roller

►The self-aligning return roller can effectively solve the deviation problem of return belt.

►EXCT self-aligning return roller have the ability to pivot at the center guided by edge rollers which in turn aligns the belt.

FEATUREs

Please refer to:

www.youtube.com/embed/9RE9nTYwHDo

Strict Quality

Control

The quality of roller directly affect the quality of the whole belt conveyor. Therefore, in order to effectively ensure the quality of our rollers and pulleys, we have established Domestic Advanced Conveyor roller Laboratory, which can carry out water resistance, radial gyration and dust prevention experiments of rollers, drop test experiment, roller axial displacement, roller resistance detection, etc. roller Laboratory, Mechanical Performance Laboratory and roller static balance test bench can be used to test the roller dynamic balance, static balance, ultrasonic flaw detection, paint film thickness, hardness inspection etc.

.jpg)