Belt Conveyor

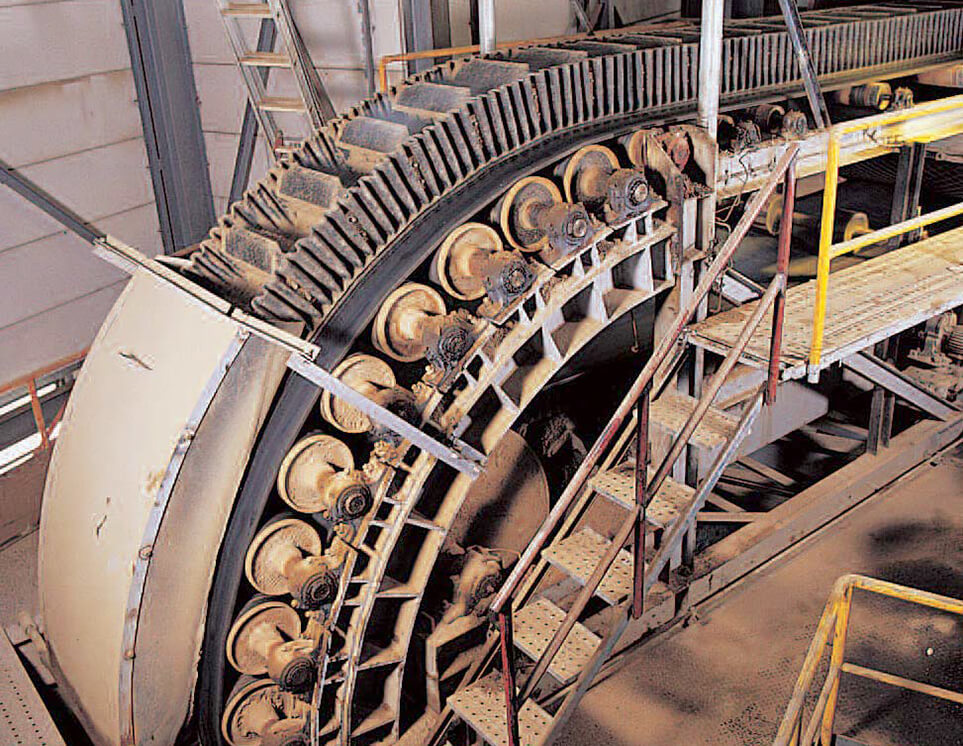

The belt conveyor is one of the best options for bulk materials handling equipment . It can continuously transport materials from one place to another place. Belt conveyor consist of conveyor belt, pulley, idlers, frame, tension devices, driving unit, protection switches and other components etc. Belt conveyor is widely used in mining, metallurgy, port, cement, grain, chemical and other industries.

CONVEYOR COMPONENTS

Driver Device

Head Pulley

Tail Pulley

Take-up Device

Conveyor Feeding Skirt

Conveyor Idler

.jpg)

Tail Pulley

Take-up Device

Conveyor Feeding Skirt

Conveyor Idler

TECHNICAL SPECIFICATIONS

| Belt Width | Up to 2.4m |

| Belt Length | 3,000m + |

| Capacity | > 8,000 m³/h |

| Belt speed | Up to 6.0m/s |

| Max Incline | Maximum 25º |

| Drive Type | Motorized pulley | Geared motor unit | Motor+fluid coupling+gear box |

| Belt Options | Antistatic| Fire resistant | Oil resistant | Hard wearing | corrosion resistant |

| Tension Unit | Below 100m – screw type tail tension unit | Above 100m - gravity tension unit or car type tension unit |

| Protection Switches | Speed switch | Belt Sway Switches | Pull-cord switch | Blockage sensor |

| Construction Materials | Conveyor case and internals - stainless or coated mild steel | Conveyor support structure - galvanised mild steel |

| Conveyed Materials | Wet or dry bulky materials in the form of crumbs, grains, pellets, shreds, dust, powder, flake, or crushed products of bio-matter, sludge and aggregate. |

APPLIED INDUSTRIES AND FIELDS

.jpg)

Coal conveying system of power plant

Port storage yard transfer conveying system

Raw material conveying system of steel mill

Open-pit mine conveying system

Bulk conveying system for cement plant

Sand-gravel aggregate conveying system

FEATURES AND BENEFITS

| Optimum Performance | |||||

| Optional self-aligning idlers can effectively prevent belt deviation. |

|||||

| Stable operation, no relative movement between the material and the conveyor belt, to prevent materials spillage and damage. |

|||||

| Increased Safety | |||||

| Skirts fitted at the feeding point, fully sealed hood at the head section, improve the working environment. |

|||||

| All kinds of protection switches give early warning of possible accidents. |

|||||

| Lower Maintenance Cost | |||||

| Automatic control, reduce maintenance personnel, save laborcosts.Interchangeable standardized spare parts to reduce purchase cost. |

|||||

| Rapid replacement of spare parts, significantly reducing costly downtime. |

| Guaranteed Quality | |||||

| Over 30 years of professional manufacturing experience and more than thousands of successful projects for end users at home and abroad. |

|||||

|

Scientific design, advanced processing equipment,

experienced technicians and skilled workers, completequality inspection system to ensure the quality of the products. |

SUCCESS PROJECT IN VARIOUS INDUSTRIES

Project name: 200,000-ton ore berth project of Dandong Port

Material name: Iron ore Handling capacity: 5,000t/h

Belt width: 1,800mm Belt length: 4,960m

Belt speed: 4.0m/s Installation angle:5°

End user name: Dandong Port Group Co., Ltd

Project name: Long distance belt conveyor is used for lignite transportation in opencast coal mine

Material name: Lignite Handling capacity: 2,200t/h

Belt width: 1,600mm Belt length: 1,562m

Belt speed: 2.5m/s Installation angle: -6°~+4°

End user name: Shanxi Datong Mining Group Co.,Ltd

Project name: Heat-resistant belt conveyors are used to transport clinker in cement plants

Material name: Cement clinker Handling capacity: 800t/h

Belt width: 1,000mm Belt length: 320m

Belt speed: 1.6m/s Installation angle: 14°

End user name: Henan Lantian Cement Co.,Ltd

-pipe-belt-project-name-overland-belt-conveyor-is-used-to-transport-coal-for-coal-fired-power-plant.jpg)

Project name: Overland belt conveyor is used to transport coal for coal-fired power plant

Material name: Fuel coal Handling capacity: 1,200t/h

Belt width: 1,400mm Belt length: 3,620m

Belt speed: 2.0m/s Installation angle: 0°

End user name: Yuneng Power Generation Co., Ltd

SPECIFICATIONS

| Belt Conveyor Technical Specifications | ||||||||||

| Belt width(mm) | Belt speed (m/s) | |||||||||

| 0.8 | 1.0 | 1.3 | 1.6 | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 6.5 | |

| Capacity (m³/h) | ||||||||||

| 500 | 69 | 87 | 108 | 139 | 174 | 217 | ||||

| 650 | 127 | 159 | 198 | 254 | 318 | 397 | ||||

| 800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | |||

| 1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | ||

| 1200 | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2971 | ||

| 1400 | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 4130 | ||

| 1600 | 2186 | 2733 | 3444 | 4373 | 5466 | |||||

| 1800 | 2795 | 3494 | 4403 | 5591 | 6989 | 9083 | ||||

| 2000 | 3470 | 4338 | 5466 | 6941 | 8676 | 11277 | ||||

| 2200 | 6843 | 8690 | 10863 | 14120 | ||||||

| 2400 | 8289 | 10526 | 13158 | 17104 | ||||||

| Remark:Capacity is caculated by material horizontal conveyoring ,20°Operating stacking Angle,35°roller groove Angle . | ||||||||||

BELT CONVEYOR BROCHURE

Submit inquiry

Related Products

Contact us

E-mail: info@exctmach.com

Hotline: +86 18153098776

Wechat: +86 18153098776

WhatsApp: +86 18153098776

.jpg)

.jpg)