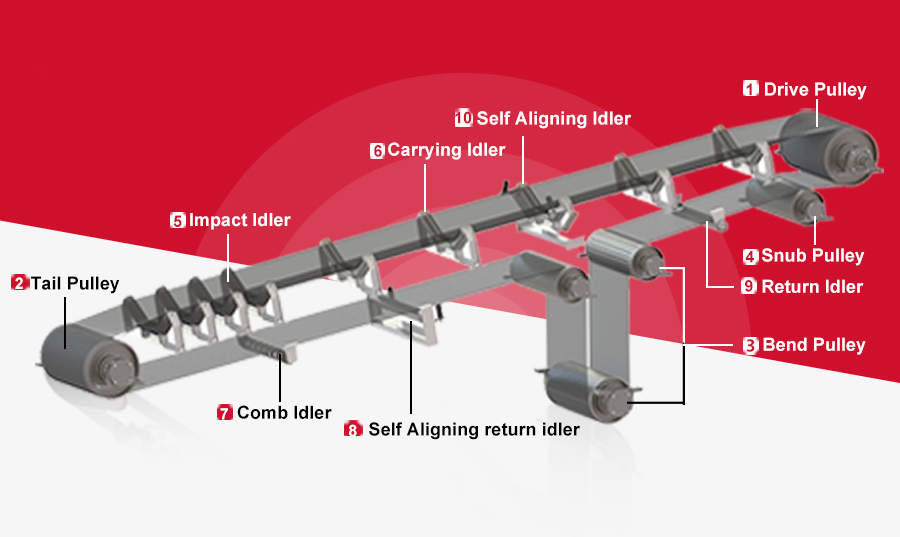

Conveyor Idler

The conveyor idler is an important part of any conveyor system because they are used to effectively support the conveyor belt and bulk materials. Conveyor idlers/rollers consist of housing, shaft, bearing, housing, seals and snaps. We mechanical conveyor idlers/rollers has unique structure, reasonable accessories, accurate assembly, large capacity and long service life.

BASIC INFORMATION

| Standard | JIS / CEMA / DIN / ISO / GB / AS / GOST |

| Idler Dia | 60-250mm |

| Idler Length | 150—3000mm Face Length |

| Shaft Dia | 20-60mm |

| Bearing Size | 6204-6312 |

| Bearing Brands | SKF, FAG, NSK, LYC, HRB, or ZWZ |

| Seal Type | Labyrinth Seal Structure |

DIFFERENT TYPES

OF IDLER SETS

There are two types of idler rollers: carrying idlers and return idlers. They are located on the support side and return side of the conveyor. These idlers have many types and functions due to specific applications.

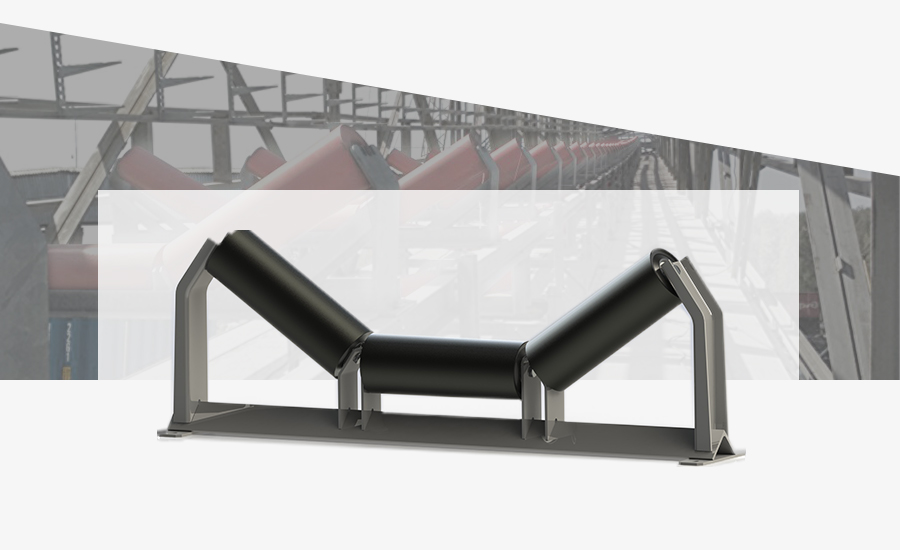

Trough Idler

►Trough idlers are the most commonly used on the belt conveyor.

►The groove angles of EXCT trough idler sets are 10°,20°,35°,45°, and can customize production according to different standards by customers, such as JIS, CEMA, DIN, ISO, GB, AS, GOST.

►Trough idlers are the most commonly used on the belt conveyor.

►The groove angles of EXCT trough idler sets are 10°,20°,35°,45°, and can customize production according to different standards by customers, such as JIS, CEMA, DIN, ISO, GB, AS, GOST.

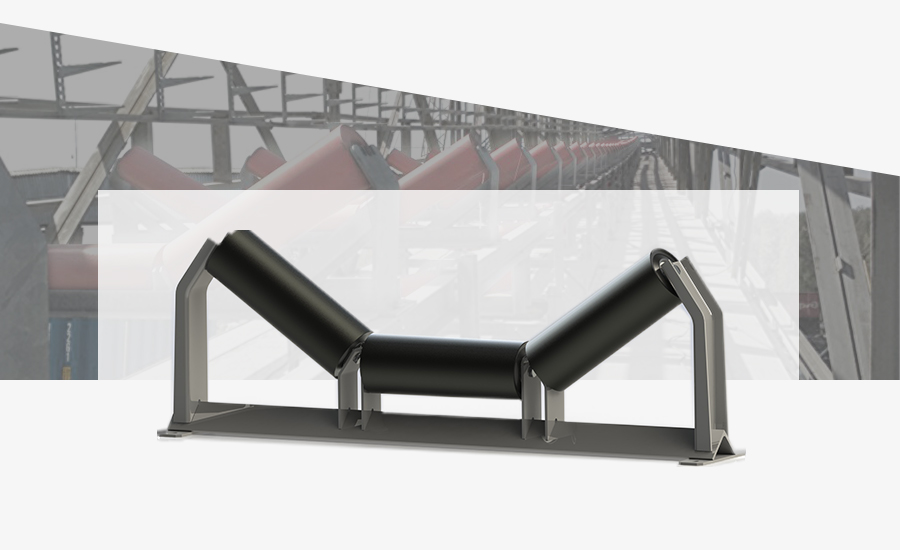

Impact Idler

►The impact idlers are generally installed in the area where the belt conveyor receives materials.

►The surface of the impact idler is rubber ring which absorb impact forces and minimize the damage of materials to the belt.

►The surface of the impact idler is rubber ring which absorb impact forces and minimize the damage of materials to the belt.

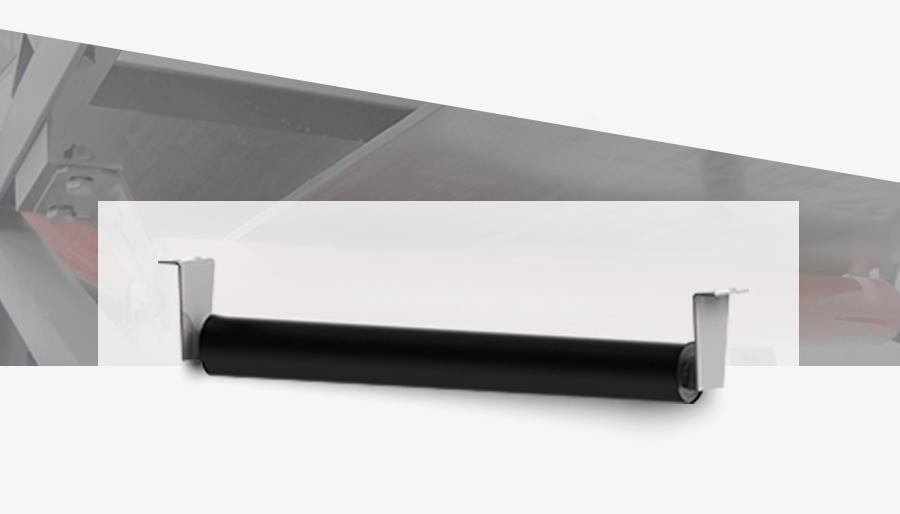

Return Idler

►The return idlers are used to support the belt to prevent stretching and sagging.

►EXCT return idler sets consist of a single idler mounted on two drop brackets.

Comb Idler

►The comb idler can prevent the belt from deviating and clean the adhesive on the belt

►Especially, when the belt conveyor transports sticky materials, the most difficult problem to solve is how to remove the materials stuck on the belt. EXCT's comb idlers are one of the best options to solve this problem.

Self Aligning Return Idler

►The self-aligning return idler can effectively solve the deviation problem of return belt.

FEATURES

EXCT has advanced automatic-flexible idler production line, which ensures that the idler rotational damping coefficient, radial run-out,axial displacement and other key performance indicators can meet different national and industry standards.

Please refer to:

www.youtube.com/embed/cr4-PBAxp00

STRICT QUALITY

CONTROL

The quality of idler directly affect the quality of the whole belt conveyor. Therefore, in order to effectively ensure the quality of our idlers and pulleys, we have established Domestic Advanced Conveyor idler Laboratory, which can carry out water resistance, radial gyration and dust prevention experiments of idlers, drop test experiment, idler axial displacement, idler resistance detection, etc. idler Laboratory, Mechanical Performance Laboratory and idler static balance test bench can be used to test the idler dynamic balance, static balance, ultrasonic flaw detection, paint film thickness, hardness inspection etc.

| Supply the various sizes of steel idlers to meet customers' require. |

| Automatic simultaneous welding, CNC milling of bearing housings. |

| Use cold drawn round steel with high surface accuracy as the shaft material. |

| Adopt precision deep-groove ball bearing of international well-known brand. |

| The idler has good dynamic and static balance performance. |

| Low idler drag and friction to protect the belt. |

| Uniquely labyrinth seals design for definitely water/dust proof. |

| Low total indicated runout (T.I.R.), Less vibration. |

| Making sure long lifetime operation. |

EXCT has advanced automatic-flexible idler production line, which ensures that the idler rotational damping coefficient, radial run-out,axial displacement and other key performance indicators can meet different national and industry standards.

Please refer to:

www.youtube.com/embed/cr4-PBAxp00

STRICT QUALITY

CONTROL

The quality of idler directly affect the quality of the whole belt conveyor. Therefore, in order to effectively ensure the quality of our idlers and pulleys, we have established Domestic Advanced Conveyor idler Laboratory, which can carry out water resistance, radial gyration and dust prevention experiments of idlers, drop test experiment, idler axial displacement, idler resistance detection, etc. idler Laboratory, Mechanical Performance Laboratory and idler static balance test bench can be used to test the idler dynamic balance, static balance, ultrasonic flaw detection, paint film thickness, hardness inspection etc.

conveyor idler catalog

Submit inquiry

Related Products

Contact us

E-mail: info@exctmach.com

Hotline: +86 18153098776

Wechat: +86 18153098776

WhatsApp: +86 18153098776

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)