Corrugated Sidewall Belt Conveyor

Corrugated sidewall belt conveyor, having the advantages of the universal belt conveyor, such as the simple structure, reliable operation, convenient maintenance etc. It also has the characteristics of large angle transmission, compact structure, and small footprint. This is the ideal equipment for conveying materials with large inclination angles and vertical lifting.

Component Introduction

.jpg)

CORRUGATED sidewall belt conveyor FEATURES

Low Investment Cost

Large angle or vertical conveying can be realized, thus reducing equipment cost and construction costs, which can save the total investment cost.

Reduced Leakage

The unique corrugated sidewalls structure can effectively reduce material leakage, improved working environment.

Reduce installation space

Large angle or vertical conveying reduce the length requirements to reach the design height when compared to conventional belt conveyor, thus reduce installation space.

Flexible Layout

Sidewall belt conveyor can also be combined with other conveying equipment, to solve the enterprise in industrial production including horizontal, inclined or vertical complex conveying requirements.

Low Energy Consumption

Large angle or vertical conveying can greatly reduce the number of rollers and belt length, which can reduce roller and belt resistance, so as to effectively reduce energy consumption.

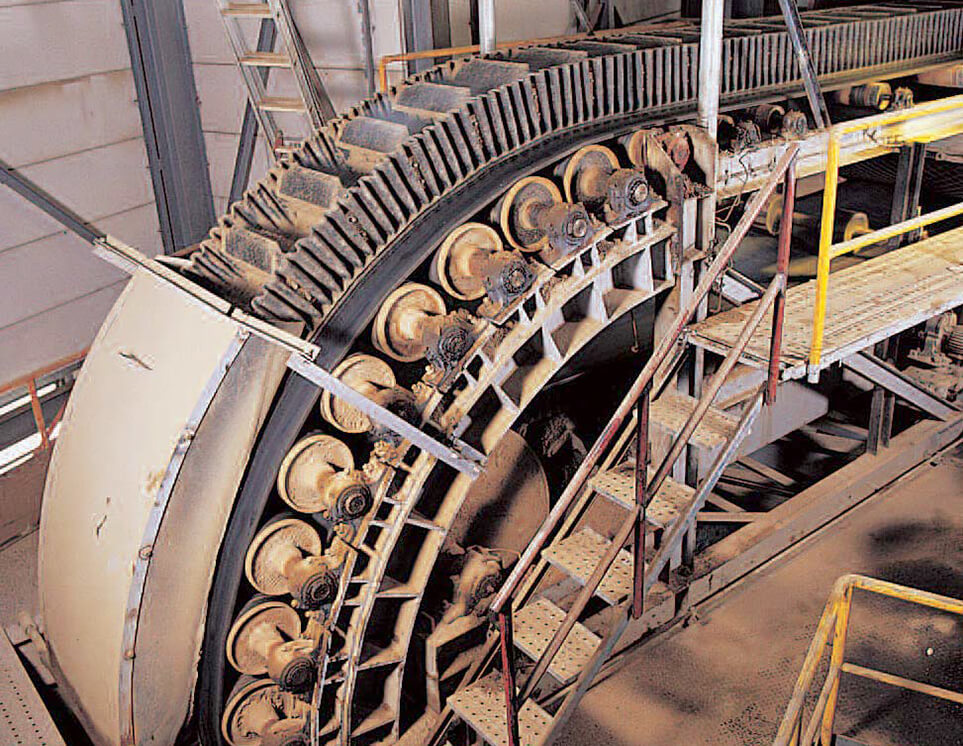

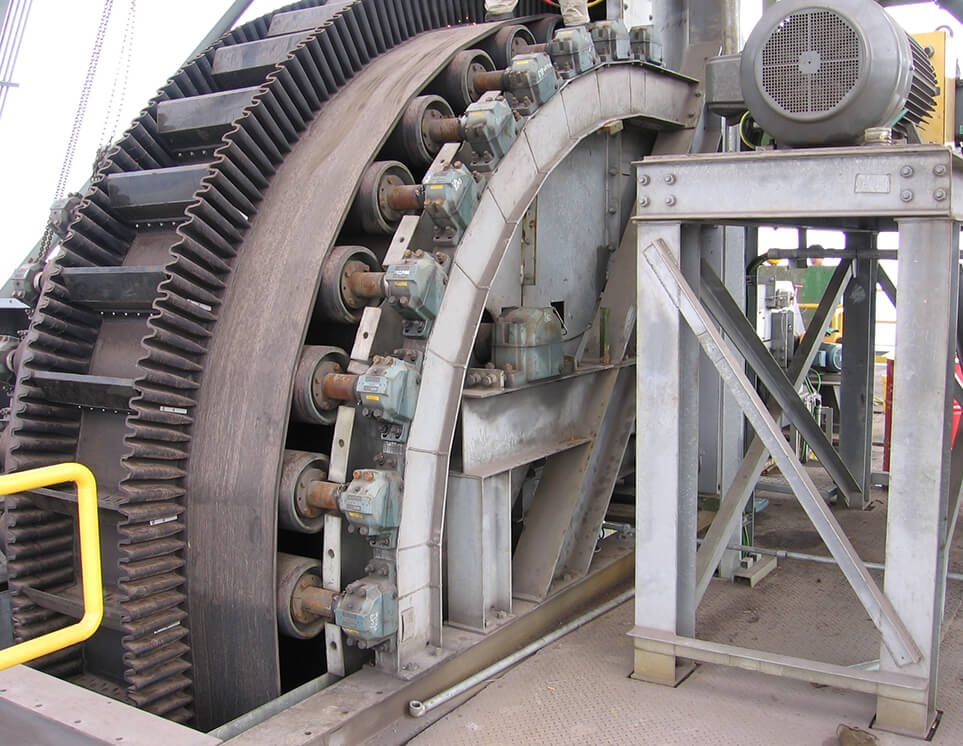

EXCT CORRUGATED SIDEWALL BELT conveyor APPLICATIONS IN VARIOUS INDUSTRY

SIDEWALL CONVEYOR BELT

The sidewall belt conveyor adopts corrugated sidewall conveyor belt with horizontal cleat which is generally divided into the base belt, sidewall and cleat.

BASE BELT

The base belt is required to have certain tensile strength and wear resistance. In order to adapt to the requirements of angle change, the longitudinal base belt must be of softness, and the transverse must have a certain rigidity. The Corrugated Sidewall Belts produced adopts transverse rigid base belt with special structure to solve the deformation problem of large size conveyor belt in the process of the return. The base belt standards are in accordance with international standard.

SIDEWALL

1. The sidewall adopts special formula and advanced production technology to ensure the flexure and fatigue resistance of sidewall edge.

2. The sidewall is strengthened with canvas and overlapped diagonally to effectively prevent the sidewall edge from tearing to increase the flexing performance.

3. Dynamic fatigue test is adopted to detect and simulate field use.

CLEAT

The production of cleat adopts special rubber formula and advancedmolding process, so that the cleat has high stiffness, wear resistance,

andimpact resistance. Therefore, it is not easy to deform when the cleat carries high-density materials.

When the cleat is connected with the sidewall, the spacing of the cleat should be considered as an integer multiple of the wave distance.

In order to prevent the cleat and sidewall in the change of angle and through the pulley, because the radius of its movement does not

match, to prevent the material from the sidewall cleat connection gap leakage and in the discharge caused by the accumulation of blind angle.

Large angle or vertical conveying can be realized, thus reducing equipment cost and construction costs, which can save the total investment cost.

Reduced Leakage

The unique corrugated sidewalls structure can effectively reduce material leakage, improved working environment.

Reduce installation space

Large angle or vertical conveying reduce the length requirements to reach the design height when compared to conventional belt conveyor, thus reduce installation space.

Flexible Layout

Sidewall belt conveyor can also be combined with other conveying equipment, to solve the enterprise in industrial production including horizontal, inclined or vertical complex conveying requirements.

Low Energy Consumption

Large angle or vertical conveying can greatly reduce the number of rollers and belt length, which can reduce roller and belt resistance, so as to effectively reduce energy consumption.

EXCT CORRUGATED SIDEWALL BELT conveyor APPLICATIONS IN VARIOUS INDUSTRY

SIDEWALL CONVEYOR BELT

The sidewall belt conveyor adopts corrugated sidewall conveyor belt with horizontal cleat which is generally divided into the base belt, sidewall and cleat.

BASE BELT

The base belt is required to have certain tensile strength and wear resistance. In order to adapt to the requirements of angle change, the longitudinal base belt must be of softness, and the transverse must have a certain rigidity. The Corrugated Sidewall Belts produced adopts transverse rigid base belt with special structure to solve the deformation problem of large size conveyor belt in the process of the return. The base belt standards are in accordance with international standard.

| Term | Model | Type | Standard cover thickness* | Min.pulley (ø) | |

| Textile | XE |  |

250/2 | 4:2 | 200 |

| 400/3 | 4:2 | 315 | |||

| XE+1 |  |

250/2+1 | 3:1,5 | 200 | |

| 315/2+1 | 4:2 | 250 | |||

| 400/3+1 | 315 | ||||

| 500/3+1 | 400 | ||||

| XE+2 |  |

400/3+2 | 4:2 | 315 | |

| 500/3+2 | 400 | ||||

| 630/4+2 | 500 | ||||

| 800/5+2 | 5:3 | 630 | |||

| 1000/5+2 | 800 | ||||

| 1250/5+2 | 1000 | ||||

| XE-SC+2 |  |

400/3+2 | 4:2 | 315 | |

| 500/3+2 | 400 | ||||

| 630/4+2 | 500 | ||||

| 800/5+2 | 5:3 | 630 | |||

| 1000/5+2 | 800 | ||||

| 1250/5+2 | 1000 | ||||

| Steel | XST-SC+2 |  |

1600 | 8:8 | 1250 |

| 2000 | |||||

| 2500 | 1400 | ||||

| 3150 |

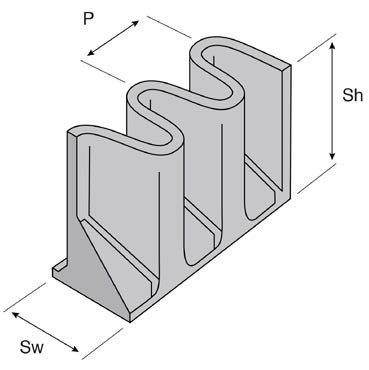

SIDEWALL

1. The sidewall adopts special formula and advanced production technology to ensure the flexure and fatigue resistance of sidewall edge.

2. The sidewall is strengthened with canvas and overlapped diagonally to effectively prevent the sidewall edge from tearing to increase the flexing performance.

3. Dynamic fatigue test is adopted to detect and simulate field use.

| Model | Type | Height (Sh) | sidewall-foot width (Sw) |

pitch (P) | Weight (kg/m) |

|

Standard | 40 | 30 | 25 | 0.58 |

| 60 | 50 | 40 | 1.55 | ||

| 80 | 1.82 | ||||

| 100 | 2.2 | ||||

| 120 | 2.65 | ||||

| Textile reinforced |

120 | 75 | 63.2 | 3.2 | |

| 160 | 4.76 | ||||

| 200 | 6.45 | ||||

| 240 | 7.5 | ||||

| 250 | 6.37 | ||||

| 280 | 8.9 | ||||

| 300 | 9.33 | ||||

| HD | 300 | 100 | 83 | 12.1 | |

| 400 | 18.72 | ||||

| 500 | 16.8 |

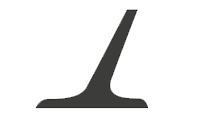

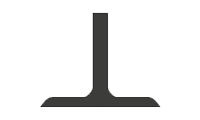

CLEAT

The production of cleat adopts special rubber formula and advancedmolding process, so that the cleat has high stiffness, wear resistance,

andimpact resistance. Therefore, it is not easy to deform when the cleat carries high-density materials.

When the cleat is connected with the sidewall, the spacing of the cleat should be considered as an integer multiple of the wave distance.

In order to prevent the cleat and sidewall in the change of angle and through the pulley, because the radius of its movement does not

match, to prevent the material from the sidewall cleat connection gap leakage and in the discharge caused by the accumulation of blind angle.

| Model | Type | Height (mm) | Foot width (mm) |

C

|

C55 | 55 | 75 |

| C75 | 75 | 90 | |

| C90 | 90 | 110 | |

| C110 | 110 | 110 | |

T

|

T40 | 40 | 70 |

| T55 | 55 | 80 | |

| T75 | 75 | 100 | |

| T90 | 90 | 110 | |

| T110 | 110 | 110 | |

| T140 | 140 | 160 | |

| T180 | 180 | 160 | |

TC

|

TC75 | 75 | 85 |

| TC90 | 90 | 110 | |

| TC110 | 110 | 110 | |

| TC140 | 140 | 150 | |

| TC180 | 180 | 150 | |

| TC230 | 230 | 160 | |

| TC280 | 280 | 160 | |

TCS

|

TCS230 | 230 | 105 |

| TCS280 | 280 | 105 | |

| TCS360 | 360 | 200 | |

| TCS470 | 470 | 200 |

Submit inquiry

Related Products

Contact us

E-mail: info@exctmach.com

Hotline: +86 18153098776

Wechat: +86 18153098776

WhatsApp: +86 18153098776

.jpg)

.jpg)

.jpg)