Conveyor Pulley

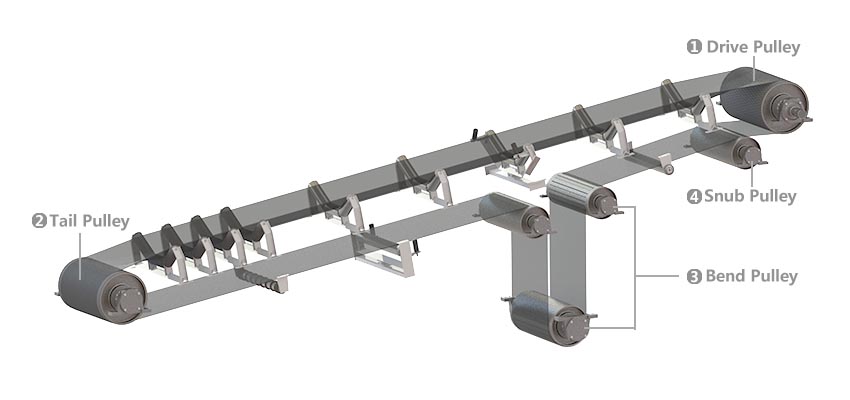

The conveyor pulley is a main part of the belt conveyor system which can draws the belt running, changes the running direction and tensions the belt etc. According to the purpose and installation position of the conveyor pulley, we can classify conveyor pulley into head pulley, tail pulley, bend pulley, snub pulley and so on. The conveyor pulley should bear the forces imposed by both conveying load and belt tension.

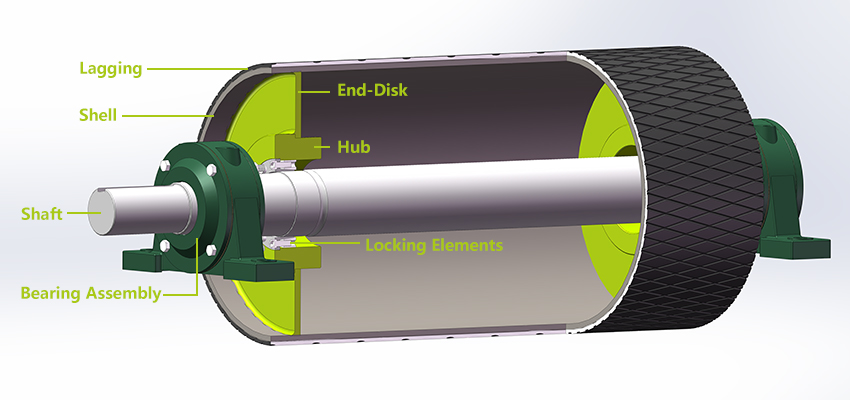

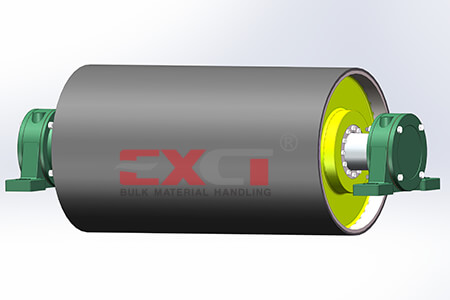

CONVEYOR PULLEY STRUCTURE & FEATURES

| Different types of Laggings can meet all kinds of complex engineering requirements. |

| Advanced welding technology ensures the connection strength between Shell and End-Disk. |

| High-strength Locking Elements can satisfy torque and bending requirements. |

| T-shape End-Discs provide highest performance and reliability. |

| The standardized Bearing Assembly makes it more convenient for the end user to replace it. |

| Excellent raw material and advanced processing technology enable the shaft can withstand enough torque. |

| Low maintenance for continued operation and low total cost of ownership. |

| Scientific design process incorporating Finite Element Analysis. |

BASIC INFORMATION

| Classes | CEMA/Heavy Duty/Mine Duty/Extreme Duty/True Engineered Class |

| Pulley Dia | 150 — 2,500mm |

| Face Length | 300 — 3,000mm |

| Shaft Dia | Up to 585 mm |

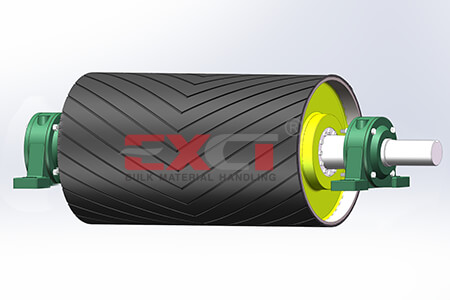

| Lagging Type | Diamond/Plain/Ceramic/Chevron/Circumferential/Replaceable slide lag |

| Bearing Brands | SKF, FAG, NSK, LYC, HRB, or ZWZ |

DIFFERENT KINDS OF CONVEYOR PULLEYS

| 1.Drive pulley |

| Drive pulleys, which can also be the head pulley, are driven by power transmission unit to propel the belt and material to the discharge. For better traction, the head pulley is usually lagged. |

| 2.Tail pulley |

| The tail pulley is located at the end point of the belt conveyor. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members. |

| 3.Bend pulley |

| The Bend Pulley is used for changing the direction of the belt. The Bend Pulley is usually installed at the tail part or the vertical take-up device when the belt direction need to 180° bending. |

| 4.Snub pulley |

| A snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle. |

LAGGING MATERIALS OF CONVEYOR PULLEY

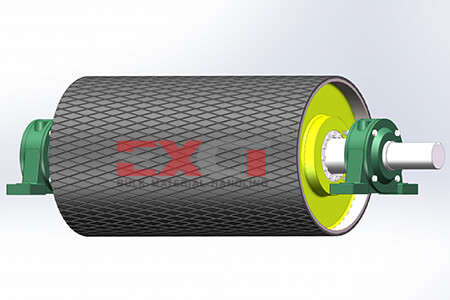

Diamond Lagging Pulley

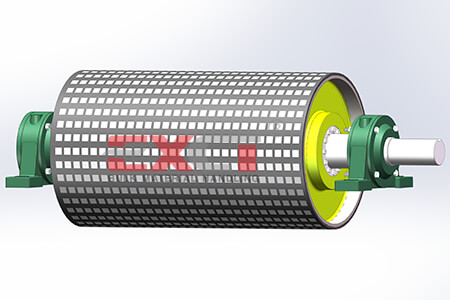

Ceramic Lagging Pulley

Plain Lagging Pulley

Chevron Lagging Pulley

CONVEYOR PULLEY PROCESS EQUIPMENT

Submit inquiry

Contact us

E-mail: info@exctmach.com

Hotline: +86 18153098776

Wechat: +86 18153098776

WhatsApp: +86 18153098776